This video has been corrected. The AOC small oil-free and water-free air pump is connected internally, and the needle tube type is connected to a high-pressure air pump.

It’s best to use this air valve, otherwise you need to turn off the air pump manually

I have received my solenoid, and hooked everything up.

I am going to be running both air assists. For the needle type, where does the end of the needle need to point to?

Point the needle air nozzle to the laser focus of the material

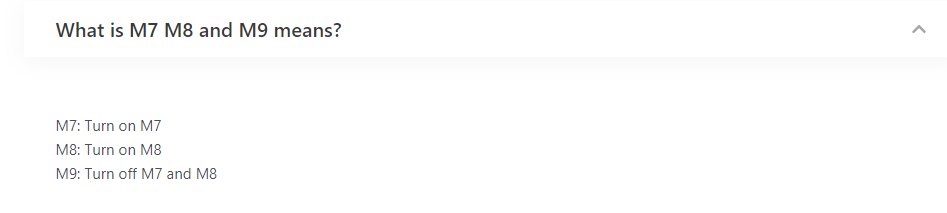

I have everything connected, but if I try to select M7 air assist in Lightburn, it deselects M8. How do I get both air assists (internal and needle) to operate at the same time in lighburn?

https://neje99.com/faq/how-to-test-m7-m8-at-grbl.html

M7: Turn on M7

M8: Turn on M8

M9: Turn off M7 and M8

Thanks Jim - it works when typing in M7 under device settings and then gcode in light burn. But have to remove it everytime I cut something like acrylic.

Wish there was a toggle switch in lightburn within cuts/layers tab for both M7 and M8.

Good morning,

Dear Jim,

I would like to ask quick question. Do NEJE E80 combined with air assist set up:

- 8 bar compressor

- 24V pump (lens protection)

Will be able to fine cut 1.0 mm thick aluminium sheet ?

Regards, Przemyslaw.

450nm laser module cannot cut and engrave aluminum plate

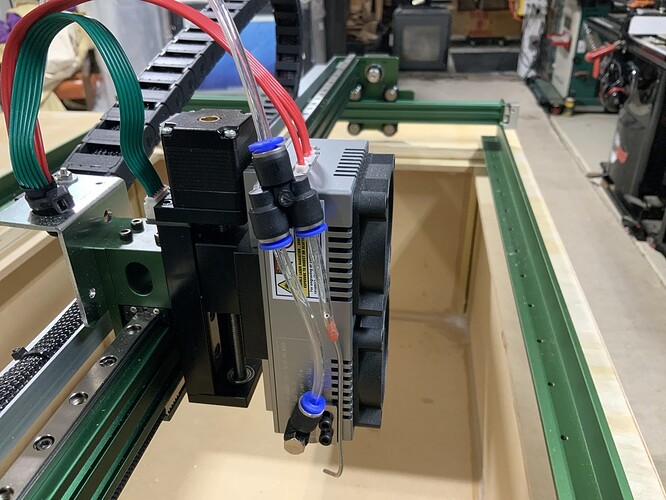

I have a 200 psi tank with oil-free compressor regulated to 90 psi piped through the shop, So rather than use 2 air sources, I used a connector which splits one 4mm tube controlled by the 24V air controller to 2 at the laser module

I bought a bag with a variety of 4mm air connectors and plenty of tubing for $12. I also got one in 8mm, also for $12, which brings the air in 8mm tubing up to the 24V controller, and the supplied 8-to-4 adapter goes into the controller.

The air from the tank goes through this for filtering and pressure regulation on the side of the laser stand.

forgot: note the really cool 1/4” NPT to 8mm tubing adapter on the output of the filters. It was in the 8mm kit I mentioned.

Hello, it looks very cool. Is the air source of this filtration method clean? Has it been tested for a long time?

The air source is an oilless air compressor in the basement below the shop, which replaced a standard oil lubed air compressor, so it is possible for there to be oil residue in the air pipes. The compressor has a water filter plumbed into its output and I drain water from the bottom of the compressor tank every month or 2 depending upon how humid the weather has been. I’ve never seen any water in the filter attached to the tank, even when there was plenty of water in the tank. I would not have any idea how to test the compressed air. It seemed that the lens cover on my NEJE Max3 might have been getting cloudy, so I went with this 3-stage filter for the Max4, hoping it is complete overkill.

I see that the 1/4” npt version like I have is back on Amazon for $48

$96 is for the 1/2” npt, but on that same page you can select 1/4” threads