Please Jack share your findings when you have tested the work that will be sent to your email.

Hi, rutysq

The software has no problem with PNG file support.

However, we did find another problem: we can’t make the machine run very slowly, in other words, we can’t make the machine run at 1mm/s, it has a maximum speed, and the minimum speed is greater than 1mm/s, but now this problem has been fixed, please update your firmware again (the version is still v2.2). Now the machine can run at very slow speeds.

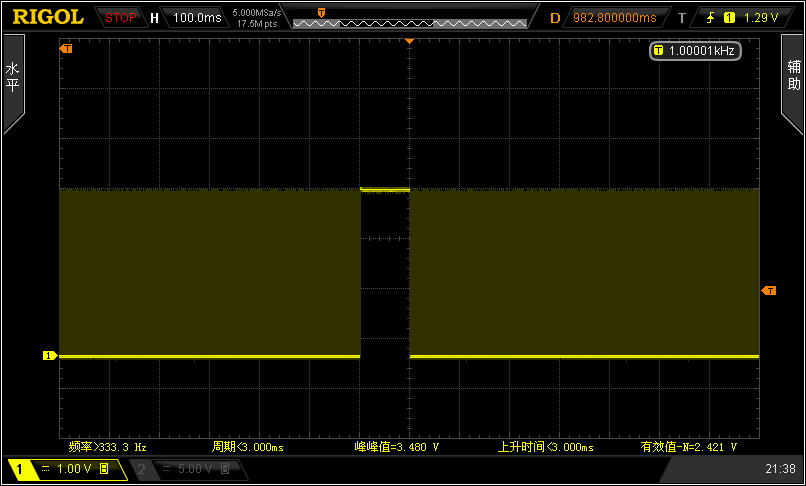

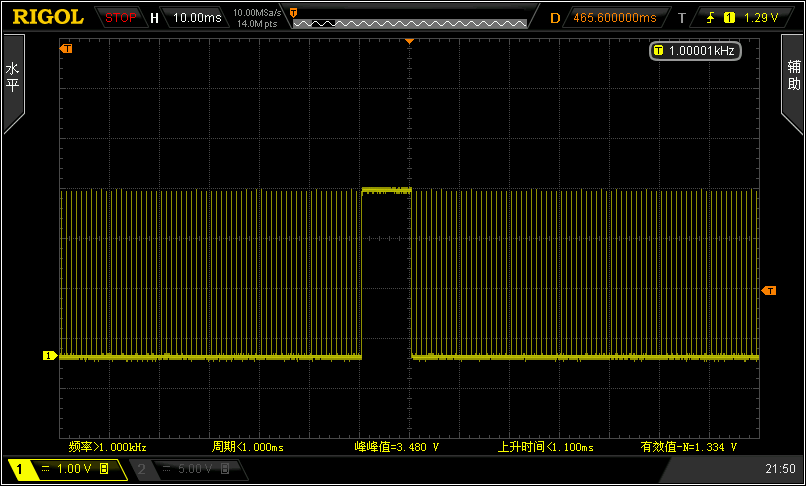

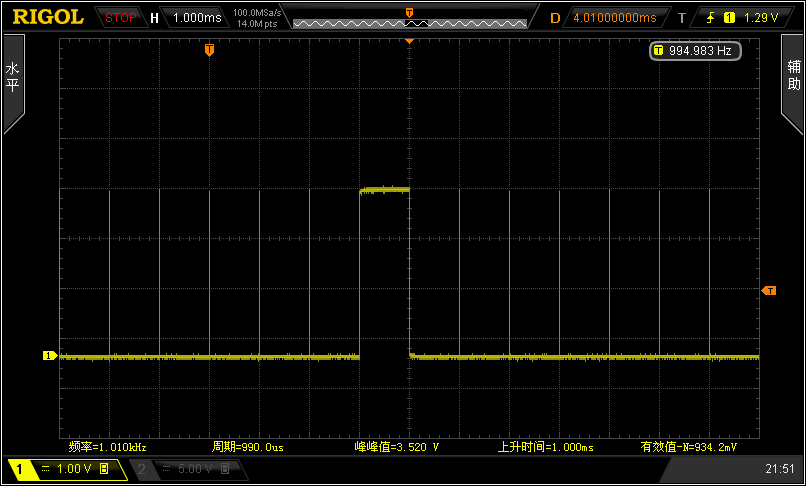

We verified the time accuracy, we set the scan speed 1mm/s and 0.1mm scan interval to scan one pixel, and we got a very beautiful 100ms laser on time. (t=s/v = 0.1mm/1mm/s = 0.1s)

(Please see the upper left corner of the picture for the time represented by each grid on the horizontal axis.)

10mm/s @ 0.1mm interval = 10ms

100mm/s @ 0.1mm interval = 1ms

If you want to get the same effect as the old software, please try

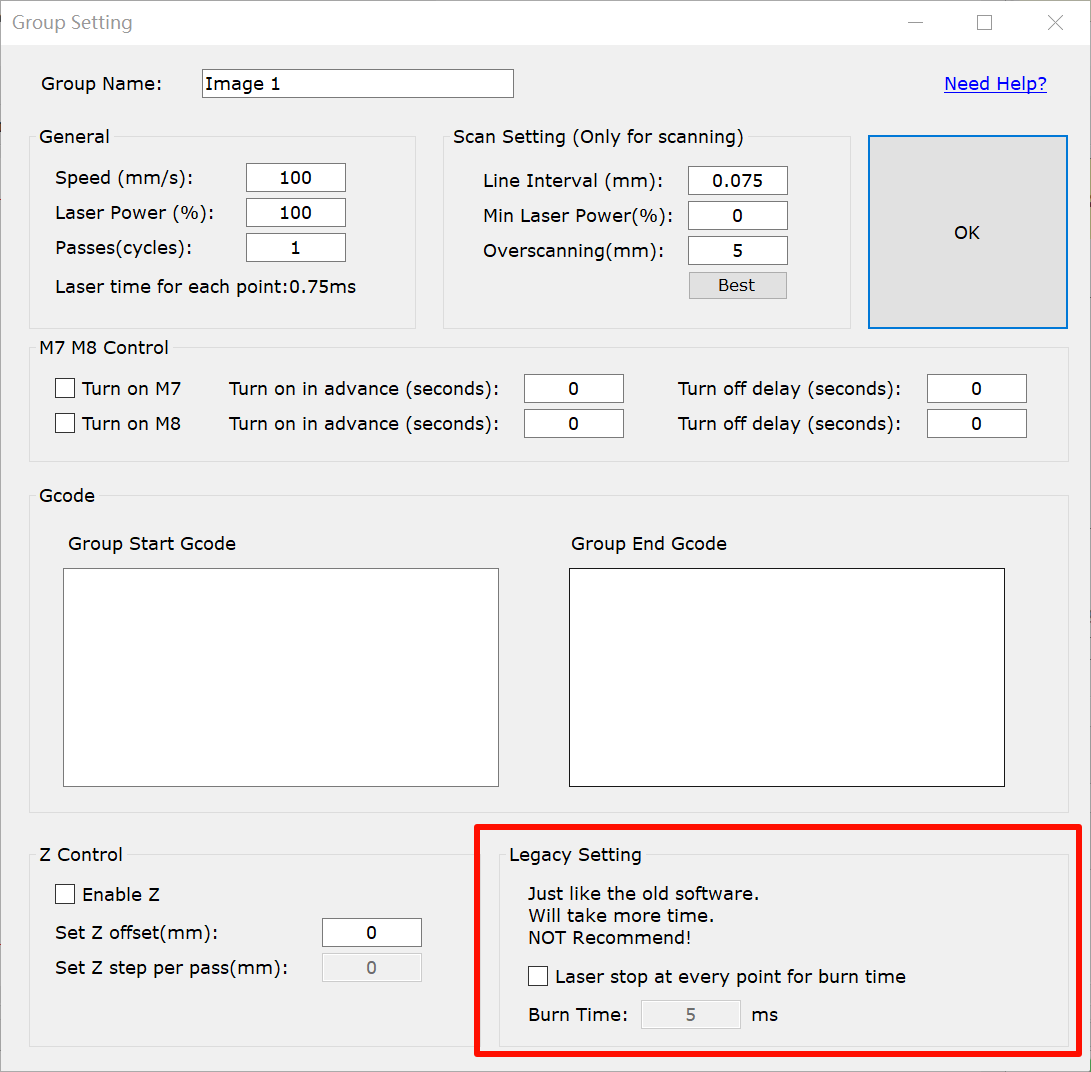

- Set line interval = 0.075mm

- Set speed = 0.075 / (old time ms)

For example, I take 10ms as an example, new speed = 0.075 / 10ms = 7.5mm/s

New preview version released, some bug fixes:

NEJE_v6.6.0_preview_2024.10.27.exe

I can’t open the new version if I’m not connected to the machine. What can I do?

The same happens in mine Ipad and mine Android.

In the current version, the software cannot be used without connecting to a machine. We plan to support operating the software without connecting to a device in the new version, but we cannot give an exact time.

Thank you very Much. ![]()

It does not support multiple machine in one computer.

If you think this feature is important, you can give us feedback here and we will develop this feature soon.

Hello!

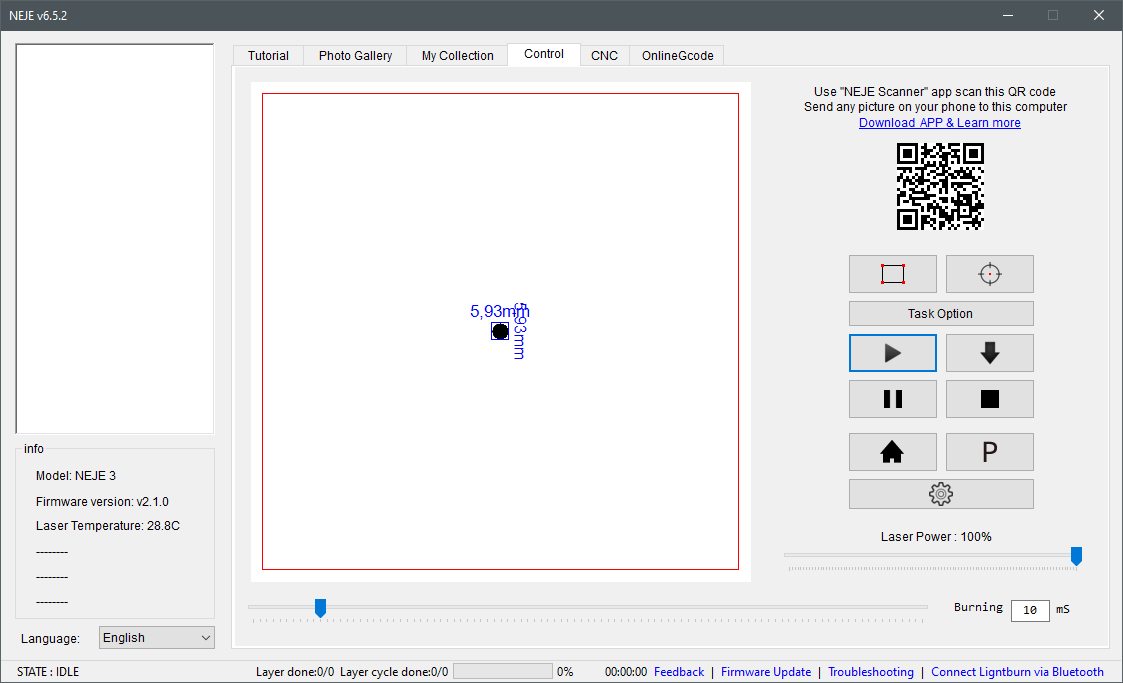

I have tryed the last version. There is a critical bug! I have just had a fire! I have loaded 17x17 mm black rectangle png. Then I have shrinked it to 6x6 mm (as I did a lot of times on the old software…) And then I have positioned the laser on the small object plased on 60x40 mm aluminum base. The machine is closed in a case when working. So I did not see. It did not accept somewhere inside the software the size, it had engraved 17x17 I guess… So it went out the base and burned the machine stand to ash…

The running speed and other thing are ok now. It seems the mashine became more powerfull or so) It engraver to dark brown (burns sttel) not to dark gray.

One more important note. When I engrave black colour png image on steel on 10 ms 100% power in 6.5.2 software the result is dark gray colour (not brown after cleanin the surface). The laser temperature is about 37-39 degrees. In 6.6 in turns to brown colour and the temperature is about 45 degrees (10-15 mm/s, 100% power, 0,1 resolution)

The new software will make your device run faster, it changes the operation mode, so the previous experience of burning time will not work, we are adding a burning time control mechanism similar to the old software to the new software.

Please do not leave the device when it is working to avoid fire.

If you think there is a problem with the new software, please provide a detailed description, thank you.

Hi Jack. Can you please add X and Y rulers in Centimeters and Inches to the work area of the software? Will the new software be compatible with Neje 2 series please?

Thank you!!

Regarding the use of both inches and mm, this should be completed soon.

Regarding compatibility with NEJE 2 series devices, it is planned and should be released in v7.0.0, which may take some time.

Regarding the suggestion of rulers, it is planned, but the time is not determined.

Currently working on the function of Laser stop at every point for burn time

Hi every one.

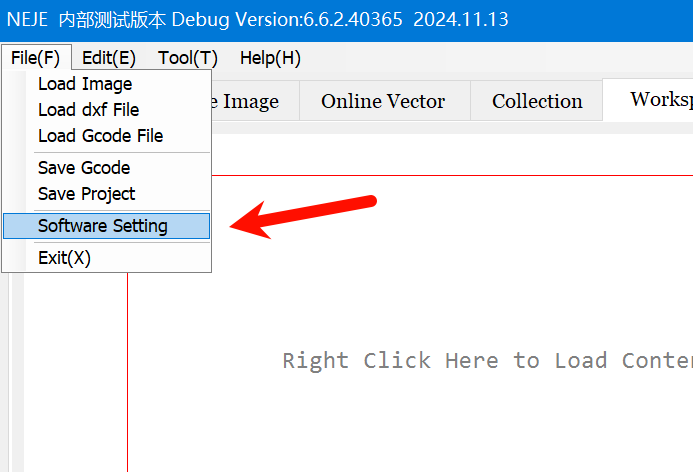

v6.6.2 is just released.

This version adds the option to stop at the exact time at each point, just like the old software.

If you have any questions, please let me know here, thank you.

Hey claufab

We added inch support to the control software, could you please test it for us? This is a preview version, please check if it works properly with inches. Thanks

Please download the preview version from the link below

NEJE_v6.6.3_preview.exe

Change your organization preferences here:

Reminder: mm in the preview positioning interface is not converted to inches

Hi Jack, I will test it this weekend.

Thank you!

Best regards

Hello!

Cant try)

NEJE v6.6.6.42360

TypeOf exception [System.NullReferenceException]

Exception message [Ссылка на объект не указывает на экземпляр объекта.]

Exception source [NEJE], thread

Exception method [Void OnMouseDown(System.Windows.Forms.MouseEventArgs)]

----------- stack trace -----------

в NEJE.CreationRender.OnMouseDown(MouseEventArgs args)

в System.Windows.Forms.Control.WmMouseDown(Message& m, MouseButtons button, Int32 clicks)

в System.Windows.Forms.Control.WndProc(Message& m)

в System.Windows.Forms.ScrollableControl.WndProc(Message& m)

в System.Windows.Forms.Control.ControlNativeWindow.OnMessage(Message& m)

в System.Windows.Forms.Control.ControlNativeWindow.WndProc(Message& m)

в System.Windows.Forms.NativeWindow.Callback(IntPtr hWnd, Int32 msg, IntPtr wparam, IntPtr lparam)