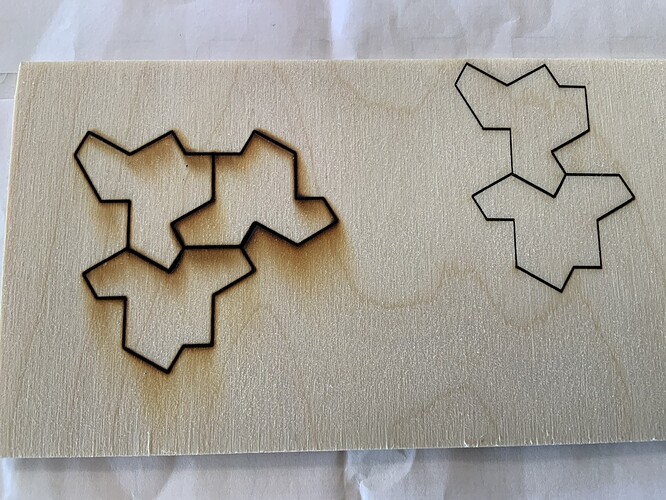

I often see questions about delaying getting pressurized air when getting started, and about the solenoid control valve that Neje sells. Here is a recent test cut:

I use the M8 port to turn on the air, but on the L is a trial cut where I forgot to turn the air valve on at the wall, so no pressure when the M8 port opened the solenoid. On the R was the next trial cut once the air was on again. Now let’s look at the back:

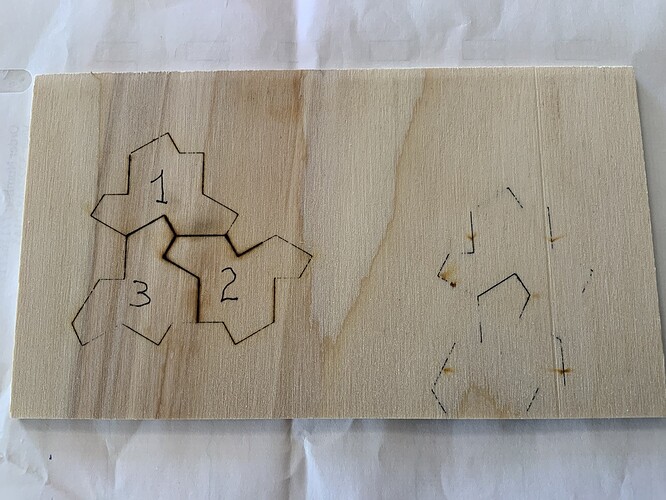

The design is made of individual tiles put against each other, so where tiles meet gets cut twice, the outsides get cut once. On the L you can see the obvious double cut where they overlap, and the lighter single cuts around the outsides. Notice that on 1 the single cuts are very nearly completely through the wood, but by 3 there are long gaps where the laser does not cut through. This is just from the very short exposure the lens cover got from cutting without air pressure in line with the laser. The smoke went up the small hole and got all the way to the lens cover. On the R you can see how the cut did get through where there were 2 passes, but not at all well where there was only 1. The lens assembly had to be cleaned, taking up time I expected that I would be cutting out my puzzles. When the air was on, I was running with 30 psi regulated to the solenoid. So, you really do need the air. You can, however, be the one turning the air on and off manually rather than telling the controller to do it for you with the air control valve, but it is a bother and easy to forget a step, as I did.