When I built my vac system for removing smoke I first used one shop vac, but wanted more air flow, so I now use 2, one hose into each lower back corner of the large box plenum I have under my 4Max, and now the air flow is adequate. I am cutting puzzles out of 3/8” birch plywood, about 17 minutes of machine time per puzzle.

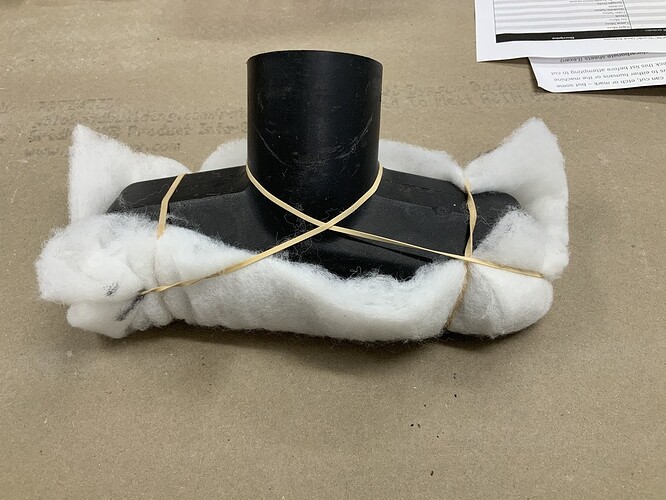

At first I used HEPA filters, but was amazed at how fast those expensive filters became completely clogged even though I could still smell smoke in the exhaust. I switched to plain general purpose filters and put some polyester batting over the 2 1/2” vac hose ends inside the plenum box. They clogged right away, so I put the roughly 5” x 8” utility nozzle on to increase the area:

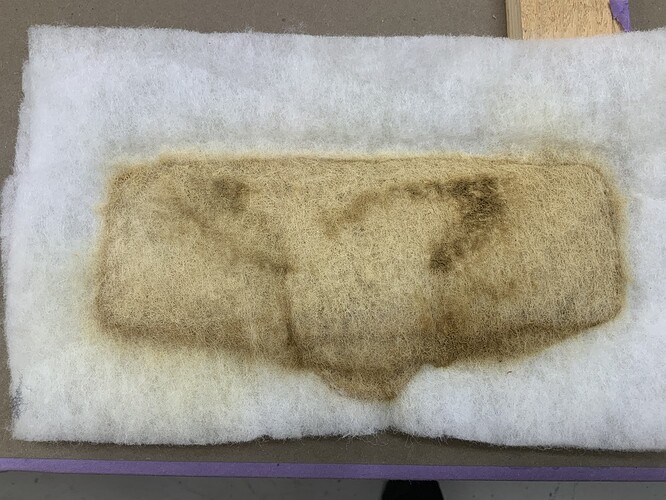

After cutting 8 of the puzzles the polyester batting looked like this:

and the back side like this:

The batting I am using is for quilting things like baby crib blankets and is available in many sizes, much cheaper on Amazon than from a specialty quilting web site. I settled on attaching with rubber bands so replacement is easy:

Considering how cheap the batting is compared to the cost of the vac filters, I am also going to wrap the pleated vac filters with a cover of the batting.

Be well, have fun, David