Hi there,

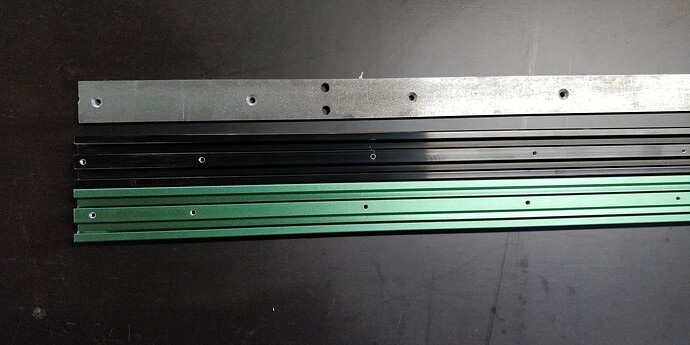

I got my modified rails and steel reinforcements bars + cross connectors.

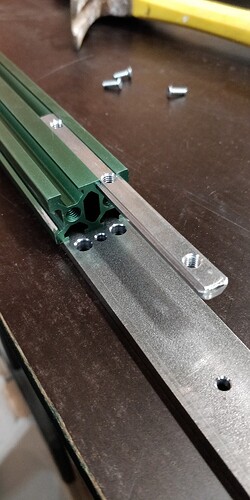

The person that CNC milled the cross connectors did not follow my technical drawings correctly because the cross connectors are a bit to wide / thick. He provided me with only 2 small cross connectors so I can test further, the thickest parts I had to cut off with a power tool.

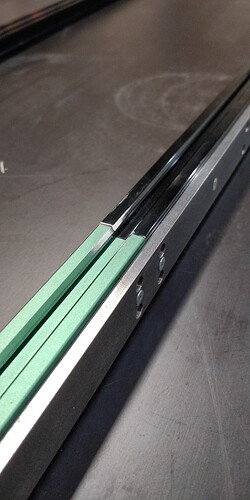

HOWEVER these cross connector are therefore perfect! Because they are a tight fit, the rails are perfecttly snugged together. The transition between these 2 rails are as good as it gets.

So I only used 2 small cross connectors of length 100mm (one in each rail, on the opposite side of the reinforcement bar)

With the steel reinforcement bars installed and only one small crossconnector on the backside, there is almost no wobble, these rails are now incredibly strong and heavy.

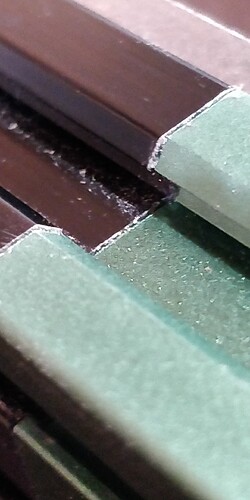

I had to file down the transition between the two rails; there was still a small step from the green rail to the black rail. I used a diamond file and 240-grit sandpaper to smooth it out, and now there is a seamless transition.

I also noticed that the groove where the GT2 belt runs is wider on the green rail. The black extension rail is slightly narrower, which means the motor wheels have to use more force compared to the green rail. So, the transition doesn’t seem even.

When I jogged around with the neje max 4 , this problem doesn’t seem to matter very much… it runs pretty smooth with no problems.

I have yet to engrave and lasercut and perform full tests, but it looks pretty okay so far.

Still concerned about wobble and the transition between the rails, I wonder if I can engrave with stunning detail without seeing a ‘bumb’

My work area is now exactly 750mm x 1610mm

I put my Xtool d1 pro with extension kit inside the neje max 4 for comparison.

Take that, Xtool hahaha

I will update you guys more, if you are intrested…